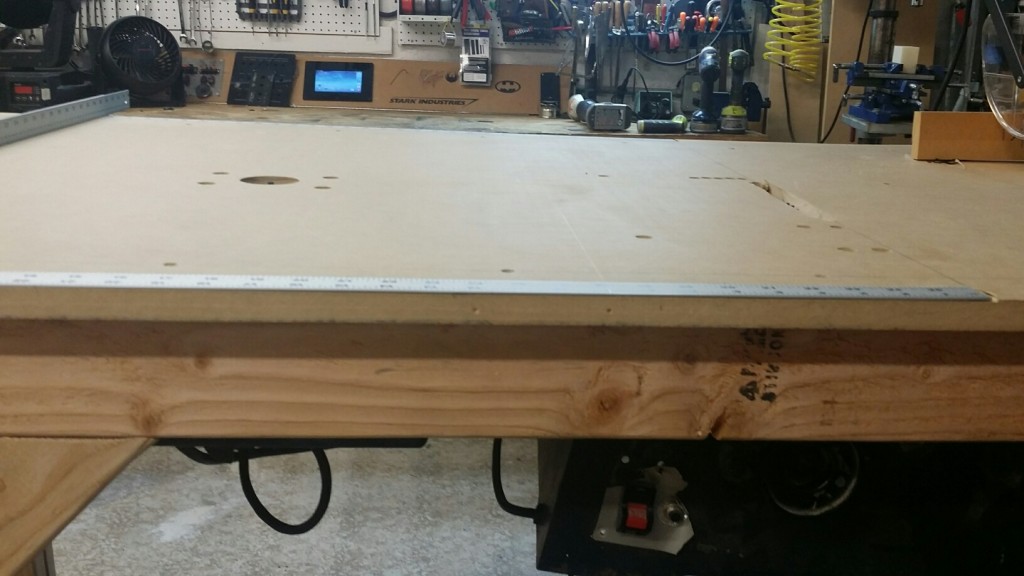

Yet again, its been awhile since I’ve posted anything on here! A lot has happened since! First off, I got a couple new toys, I picked up a vinyl plotter. This has been great for labeling things and just having fun. My other toy was upgrading my CNC Router to a bigger and faster machine. I picked up a 2×4 Warthog router, it took some work to get it running on Mach3, but has been worth it. I always liked how the industrial units had dedicated systems that used there own software. Made them cooler and so much more convenient IMO. But Mach3 is such a great easy to use piece of software that I wanted that as well. So here is what my ingenuity came up with!

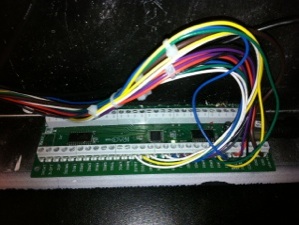

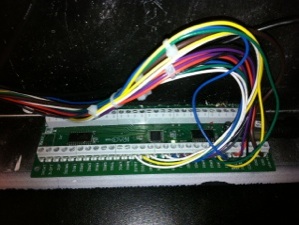

Its a pretty simple device really. All of the parts, except the “E-Stop” Button I had laying around. The Screen is just a 10” LCD I took out of kiosk system. All of the buttons and joysticks came from a box of old MAME parts I had laying around. I had a extra I-pac ( http://www.ultimarc.com/ipac1.html ) laying around, which basically makes all the buttons keyboard commands which Mach3 can see as a “hotkey”. More details later.

This definitely not the cleanest device I’ve come up with, but it will be cleaned up soon. The screen in the panel simply hooks up to the VGA output of the PC (the first one in the pic), Then I have a powered USB Hub in the panel that breaksout many USBs, this is for the Keyboard, Mouse, I-Pac and whatever else I may need like a USB stick. All of the buttons you can find on ebay if you search for “MAME Buttons” along with joysticks. They all hook into this I-Pac (this one is a bit big, but its what I had around).

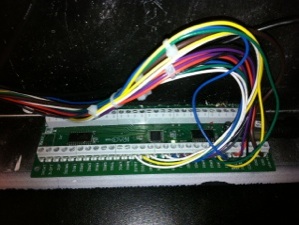

This nifty little device has screw terminals for all of your buttons. It even comes with a piece of software that allows you to program each button to each keyboard command if you’d like to be technical. This is a great way to add inputs to Mach3 without the need of a second parallel port. You simply need to download Mach3Screen ( LINK HERE ) and tell each onscreen button what “hotkey” (from the ipac) you want. Now you can add as many buttons as you can imagine for any function you want! The only hotkeys your going to want to actually program in the Mach3 app is your movement commands. Thats easy as going to System Hotkeys in Mach3. Mach3 will see all the inputs from the Ipac as keyboard commands, so it works FLAWLESSLY! You could even do limit and home switches if you’d want, but i wouldn’t recommend it.

I went ahead and used my vinyl plotter to make all of the labeling for the machine to give it that professional look. I think it came out pretty darn good!

Now, the actual electronics for running a CNC (like my warthog) is a whole other project and is not going to be explained right now in detail, but i want to show you the inside of my motor control box just so you can see the relays and power outlets.

There are a few relays in the back which control the main power, the spindle and vacuum. These get there commands directly from the switches on the panel threw a normal 9 pin serial cable. I do this for a personal preference as I dont really want the computer controlling the spindle just yet. I was a bit worried about noise at first, but I haven’t had any problems.

The panel also got the keyboard added to it, which is a very nice keyboard, its all dust and water sealed and has the mouse built in. Also includes another 12 F keys which is excellent for giving commands in Mach3. Soon I will add a MPG Pendant to go next to the keyboard and make complete. Its all mounted to a steel bar that can easily swivel around.

This really is perfect for anyone with a CNC Machine that wants to have it controlled very conveniently and not have to worry about dust and such getting into your keyboard and mouse